Use Essentials

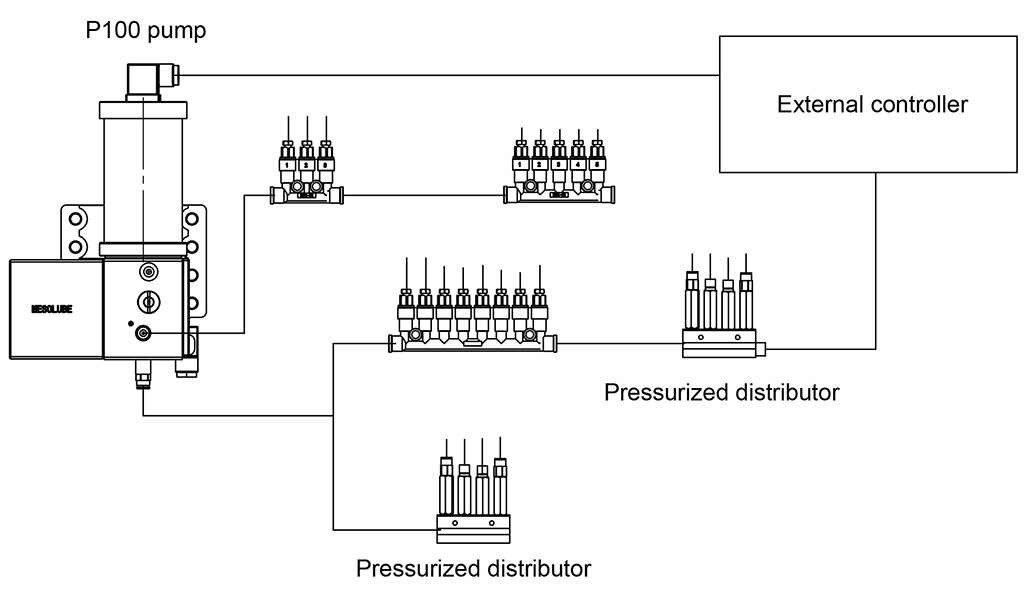

- Mount the lubrication pump as close as possible to the distributor. If there is an independent controller, it should be mounted indoors. Both the pump and the controller should be mounted in a dry place with little vibration, less dust, and easy maintenance. Protective measures should be taken where dust and moisture cannot be avoided. The hand pump should be mounted at a height of about 1 meter from the ground for easy operation. It is more convenient to mount the pump with a welding bracket.

- When the system is mounted and ready to operate, the system must be filled with grease first. Before filling the grease, the piping system must be flushed or blown with compressed air. After the dust particles are removed (the pickling and flushing system is required after welding and tapping), it is filled with clean grease.

- The lubricator is used to fill the grease lubricating pump with grease. The reservoir of the lubricator should be checked regularly. If the amount of grease is too low, the grease should be added in time to avoid the lubricator being empty.

- The reservoir cover on the lubrication pump is only used for inspection and maintenance. The cover cannot be opened to fill the grease. Grease should be filled from the grease filling inlet of the lubrication pump. It should be closed tightly at ordinary times to prevent dust and impurities from entering the reservoir.

- The single-line lubrication system has high requirements for the cleanliness of grease. It must be filled with grease of suitable viscosity according to the specifications of the pump and lubrication distributor. The filling of grease must be carried out from the pump’s refueling port, and the inlet is equipped with a filter. It should be cleaned regularly.

- The maintenance personnel should check the lubrication pipeline regularly. If the joints are found to be loose or fall off, or the tubing is cracked, they should be connected or replaced in time.

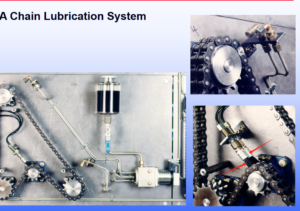

Single-line lubrication systems are widely used in mining machinery, steel, metallurgical machinery, water conservancy machinery, cement machinery, transportation vehicles, port machinery, construction machinery, forging machinery, etc.