Introduction

In various mechanical equipment, in addition to the extensive use of thin oil lubrication, grease lubrication is used in many friction pairs. Grease lubrication is a complete set of equipment that uses grease as the lubricating medium of the mechanical friction pair and supplies grease to the lubrication point through a grease pump.

According to the difference of friction pair, lubrication method and environment of use, some manual grease guns are used to add grease to the lubrication points. In some cases, a centralized grease lubrication system must be used to regularly add grease due to the large number of lubrication points.

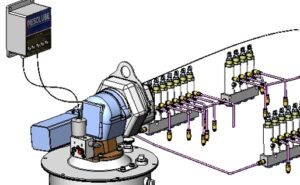

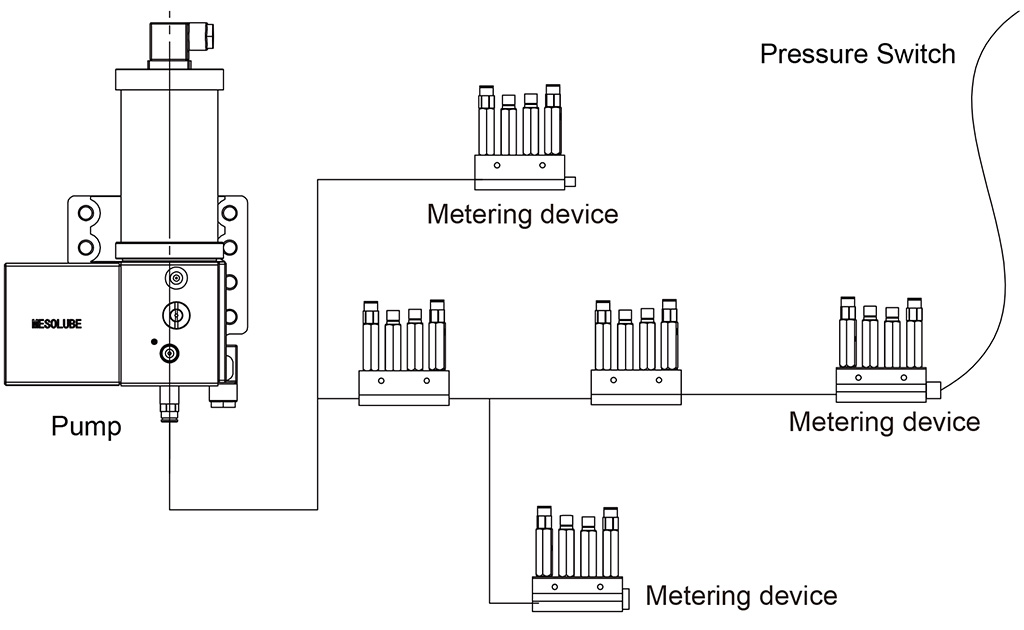

Composition of single-line lubrication system

The main unit pump (electric pump, hand pump, pneumatic pump), pressure-relief valve, tubing, lubricator, level switch, pressure switch and other accessories.

Working principle of single-line lubrication system

In the single-line centralized lubrication system, the high-pressure grease is discharged from the pump and supplied to the first-stage distributor through the main line. The grease from the first-stage distributor is supplied to the second-stage distributor through the branch line, and then supplied to the lubrication points step by step. The commands issued by the pump controller make the system operate automatically.

Features of single-line centralized lubrication system

- The grease main line needs only one line, the layout is simple, the mounting cost is low, and the system is easy to expand or shrink.

- The lubrication point of the movable part can be supplied with grease.

- Automatic lubrication can be realized for the lubrication points with compact structure, harsh environment and important parts to improve the reliability of lubrication.

- Each lubrication point can get the predetermined amount of grease, and the grease will not be wasted.

- The lubrication pumps are operated independently of each other, and the discharge volume can be adjusted or monitored separately.

- Point-to-point lubrication. Each lubricator corresponds to a lubrication point. The lubricators are independent of each other.

- It is suitable for thin oil, semi-fluid grease or grease below NLGI 1. It can be applied to NLGI 2 grease under certain conditions (such as high temperature).

- The system needs to be relieved of pressure, which is restricted in low temperature applications.

- It can lubricate 200 points at the same time