Customer Name: A smart device manufacturing company

Application site: new agricultural harvester

Installation location: the side of the workbench

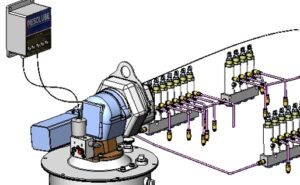

Product model: P100-152400

We have carried out regular inspections on the electric grease lubrication system users who installed the new agricultural harvester in November 2019, mainly to ensure the good operation of the centralized lubrication system, and to collect customer opinions and feedback to the company.

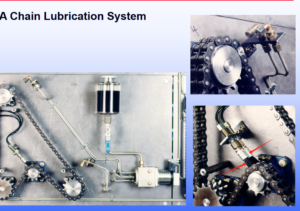

The lubrication system is installed on the side of the workbench of the agricultural harvester, and is mainly installed with our progressive electric grease lubrication system. Among them, it mainly contains a 1.5L electric grease pump, two 20-outlet progressive distributors, and two 6-outlet progressive distributors. The basic parameters of the pump: The voltage is 24VDC, and a total of 48 lubrication points need to be lubricated. .The average distance between the lubrication points and the pump is 3 meters, and the main line used by the system is about 5 meters. The system also contains a number of tube fittings, adapters, etc., all supplied by our company.

Because the customer neglected the instructions for use of our products at the beginning, and used the wrong grade of grease, the pump was in poor working condition at the beginning. After our investigation, the wrong usage was adjusted and the lubrication system was running smoothly and well.

The agricultural harvester installed with the centralized grease system performs well in work, and the lubrication points that need to be lubricated are correspondingly lubricated. In other words, each distributor can be supplied grease normally. In this way, the lubrication requirements of the harvester are indeed solved, that is, the failure rate of the equipment is reduced, the number of maintenance is reduced, and the cost of maintenance is reduced. The parts with friction loss are properly lubricated instead of insufficient or excessive, which can not only reduce the best working condition of the parts, extend the working life, but also save lubrication grease, reduce pollution, and reduce the cost of production operations.

This is the first time that our P100 lubrication pump has been applied to agricultural harvesters. After inspection, it was discovered that the progressive lubrication system composed of the pump can be used on this type of equipment. It can be seen that the application range of this series of electric grease pumps is very broad.