Customer Name: A machinery company in Shenzhen

Application site: automatic glass cutting machine

Installation position: machine measuring surface (lower right corner)

Product model: P100-07C2410

The automatic glass cutting machine is composed of a stepping or servo motor, a driver and a CNC control system, and is equipped with a cutter wheel. It can cut multiple knives at the same time, and can realize linear, irregular and circular cutting of photoelectric glass and ultra-thin glass. Therefore, the requirements for the stability and accuracy of the equipment are very high.

At present, the equipment still uses a manual grease gun for manual lubrication. Add a certain amount of grease to each lubrication point regularly. Due to the large number of equipment lubrication points (40 lubrication points), and the equipment working cycle is not fixed, so add Grease is troublesome, wastes a lot of manpower and material resources, and increases production costs. Secondly, the equipment is an automated customized equipment, and the price is relatively high. If the lubrication is improper, the equipment will wear out and stop working, which will cause not only the loss of the equipment, but also the cost of delaying production.

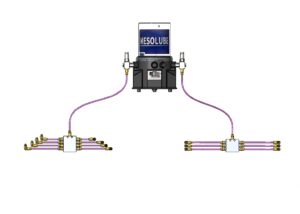

This time, we recommended the P100 series of replaceable manual grease pumps according to customer needs. The pump has a pressure relief valve and forms a single-line centralized grease lubrication system with a pressurized distributor. This system uses a total of 1 electric grease pump (cartridge version), the voltage is 24V, the 700mL capacity can replace the standard grease cartridge, the use of distributors 4 6-outlet pressurized distributors, 2 8-outlet pressurized distributors, There are also 15-meter tubing and several fittings. The pump is mounted on the side of the machine to lubricate a total of 40 lubrication points.

In this case, because the lubricated equipment has special requirements for accuracy and stability, we pay special attention to the metering quantity of the distributor in the lubrication system and its stability when customizing the plan to ensure that each lubrication point is lubricated. , We have also added a corresponding implementation monitoring device, which can issue an alarm in time when there is any abnormality in the lubrication system line, and find and repair it in time.