TA-A2B-D1 MQL Minimal Quantity Lubrication

The oil volume can be adjusted and kept stable. Air volume and lubricating oil can be controlled separately. The whole set of equipment is composed of a simple form, which can be easily installed on the processing equipment.

Description

The oil volume can be adjusted and kept stable.

Air volume and lubricating oil can be controlled separately.

The whole set of equipment is composed of a simple form, which can be easily installed on the processing equipment.

The oil can be sprayed from the outside of the tool to the processing interface through the nozzle.

The oil mist can be generated through the pipeline inside the machine tool, and it will exit through the end of the tool and reach the processing interface directly.

| Compressed air inlet | 6mm |

| Quick coupling oil/ specification tubing | 10mm |

| Oil supply volume per cycle of oil pump | 0.03~0.005cc |

| Adjustable frequency range | 1-15sec |

| The most suitable air pressure | 4-6bar |

| Ambient temperature | -10~40℃ |

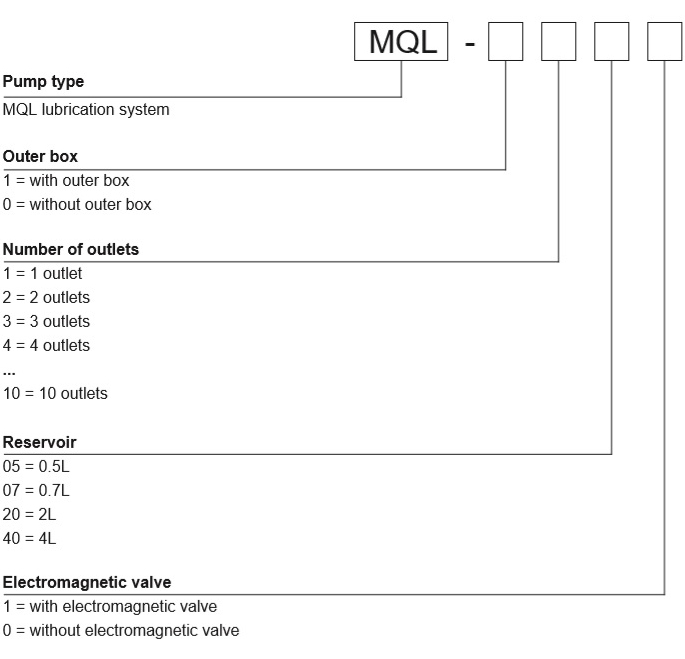

Ordercode

Specifications

The oil volume can be adjusted and kept stable.

Air volume and lubricating oil can be controlled separately.

The whole set of equipment is composed of a simple form, which can be easily installed on the processing equipment.

The oil can be sprayed from the outside of the tool to the processing interface through the nozzle.

The oil mist can be generated through the pipeline inside the machine tool, and it will exit through the end of the tool and reach the processing interface directly.

| Compressed air inlet | 6mm |

| Quick coupling oil/ specification tubing | 10mm |

| Oil supply volume per cycle of oil pump | 0.03~0.005cc |

| Adjustable frequency range | 1-15sec |

| The most suitable air pressure | 4-6bar |

| Ambient temperature | -10~40℃ |

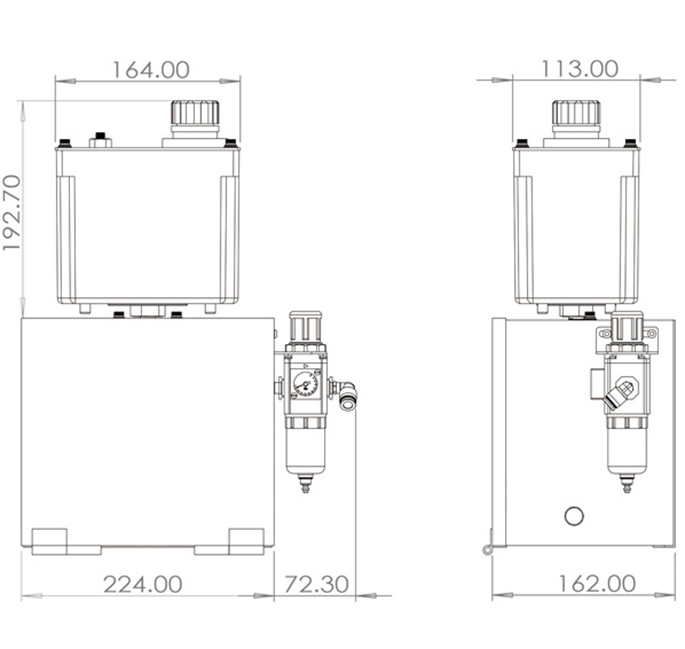

Dimensions

Applications

The amount of cutting oil consumed by the MQL micro-lubrication system is very small. Compared with the traditional metalworking cutting fluid, the minimum usage is only 1/50 of the cutting fluid consumption.

Main applications: circular saw, vertical band saw, horizontal band saw, milling machine processing, center oiling, drilling machine, punching, gear hobbing, etc.