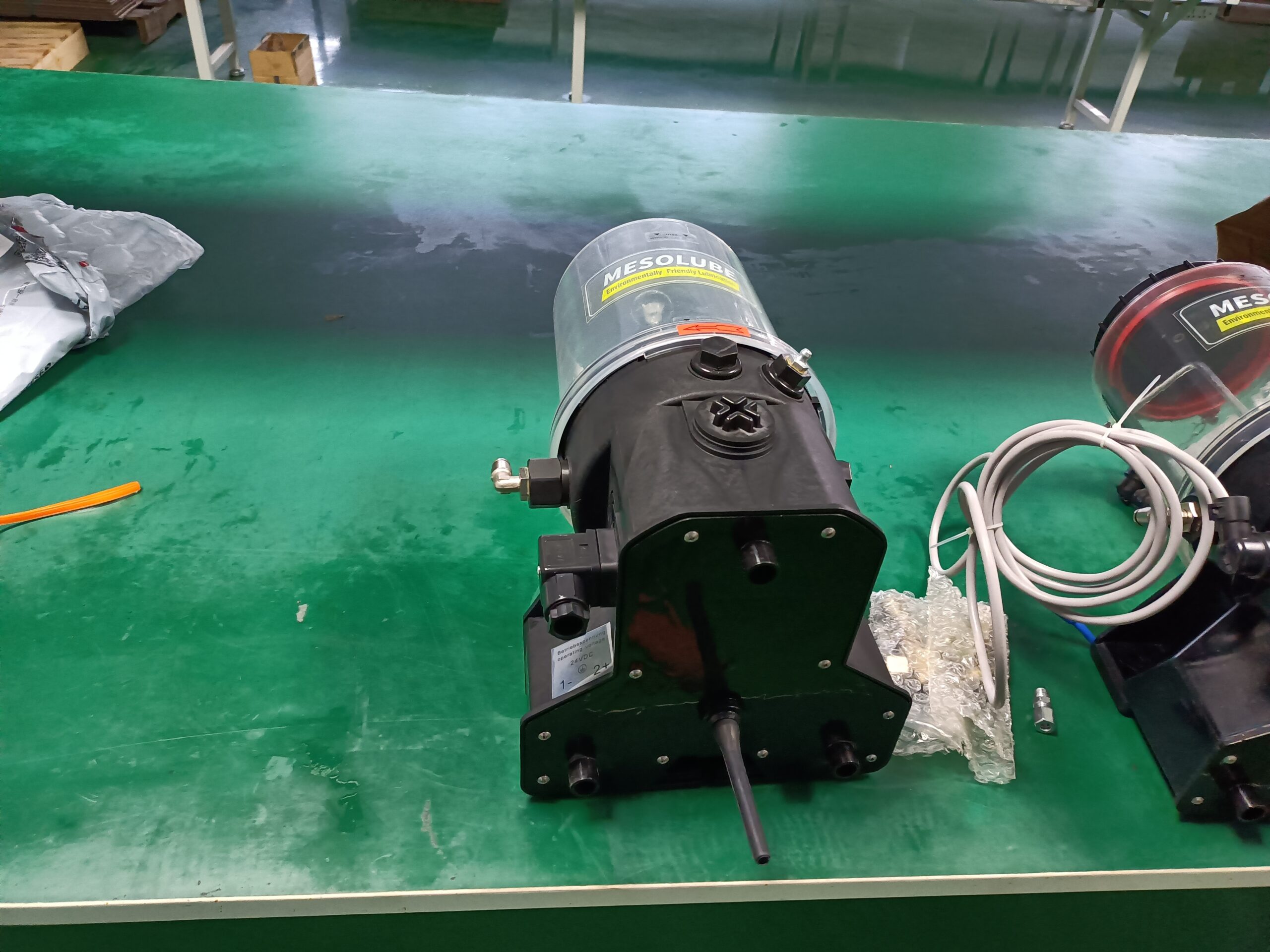

P300-2L Electrically Operated Lubrication Pump for progressive lubricaiton system

Optional control printed circuit board with different operating settings

Range of reservoir types provided

DC or AC applications

Various pumping components with different outputs are available

Description

For progressive lubrication systems

The P300lubrication pump is versatile, compact and economical. Depending on the length of the pipeline, up to 150 lubrication points can be provided. It consists of a housing with an integrated motor, a liquid storage tank with a stirring blade, a pump element with a pressure reducing valve, an oil injection nozzle and electrical connection parts. This powerful pump can drive up to three pump elements and can be equipped with a low-level control (with or without a control board).

Ordercode

| Function principle | electrically operated piston pump |

| Operating temperature V DC | –40 to +70 °C |

| Operating temperature V AC | –25 to +70 °C |

| Operating pressure | 350 bar |

| Lubricant | grease: up to NLGI 2 |

| oil with operating viscosity 40–1500 mm2/s | |

| Outlets | up to 3 |

| Metering quantity depending on pump element | 0,7-4,0 cm3/min / outlet |

| Reservoir capacity | 2; 4; 8; 11 and 15 l |

| Outlet connection | G 1/4 |

| Operating voltage | 12/24 V DC |

| 115, 230 V AC / 50 or 60 Hz | |

| Protection class | IP6K9K |

| Dimensions | |

| min. | 211 × 224 × 287 mm |

| max. | 211 × 250 × 774 |

Specifications

| Function principle | electrically operated piston pump |

| Operating temperature V DC | –40 to +70 °C |

| Operating temperature V AC | –25 to +70 °C |

| Operating pressure | 350 bar |

| Lubricant | grease: up to NLGI 2 |

| oil with operating viscosity 40–1500 mm2/s | |

| Outlets | up to 3 |

| Metering quantity depending on pump element | 0,7-4,0 cm3/min / outlet |

| Reservoir capacity | 2; 4; 8; 11 and 15 l |

| Outlet connection | G 1/4 |

| Operating voltage | 12/24 V DC |

| 115, 230 V AC / 50 or 60 Hz | |

| Protection class | IP6K9K |

| Dimensions | |

| min. | 211 × 224 × 287 mm |

| max. | 211 × 250 × 774 |

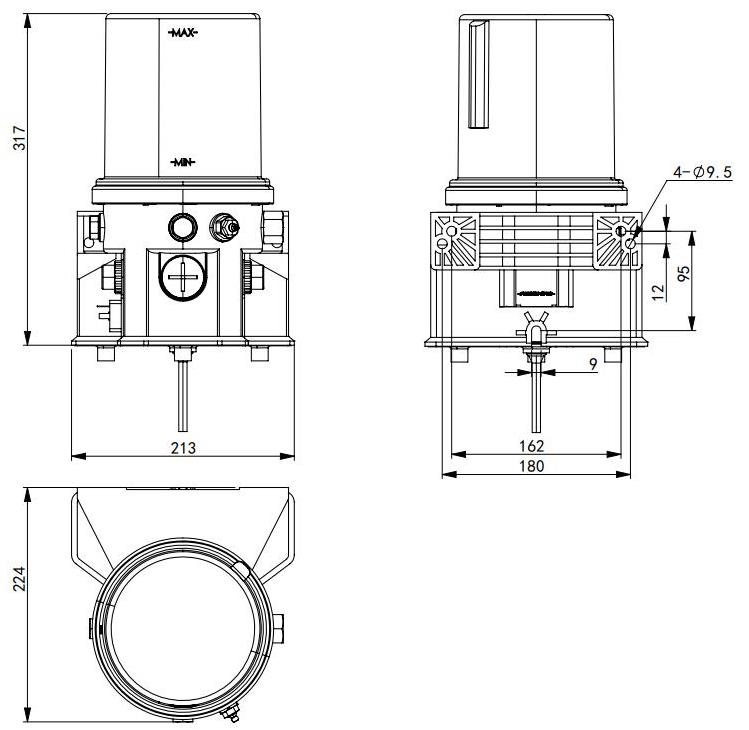

Dimensions

Please contact us for more dimensions!

Applications