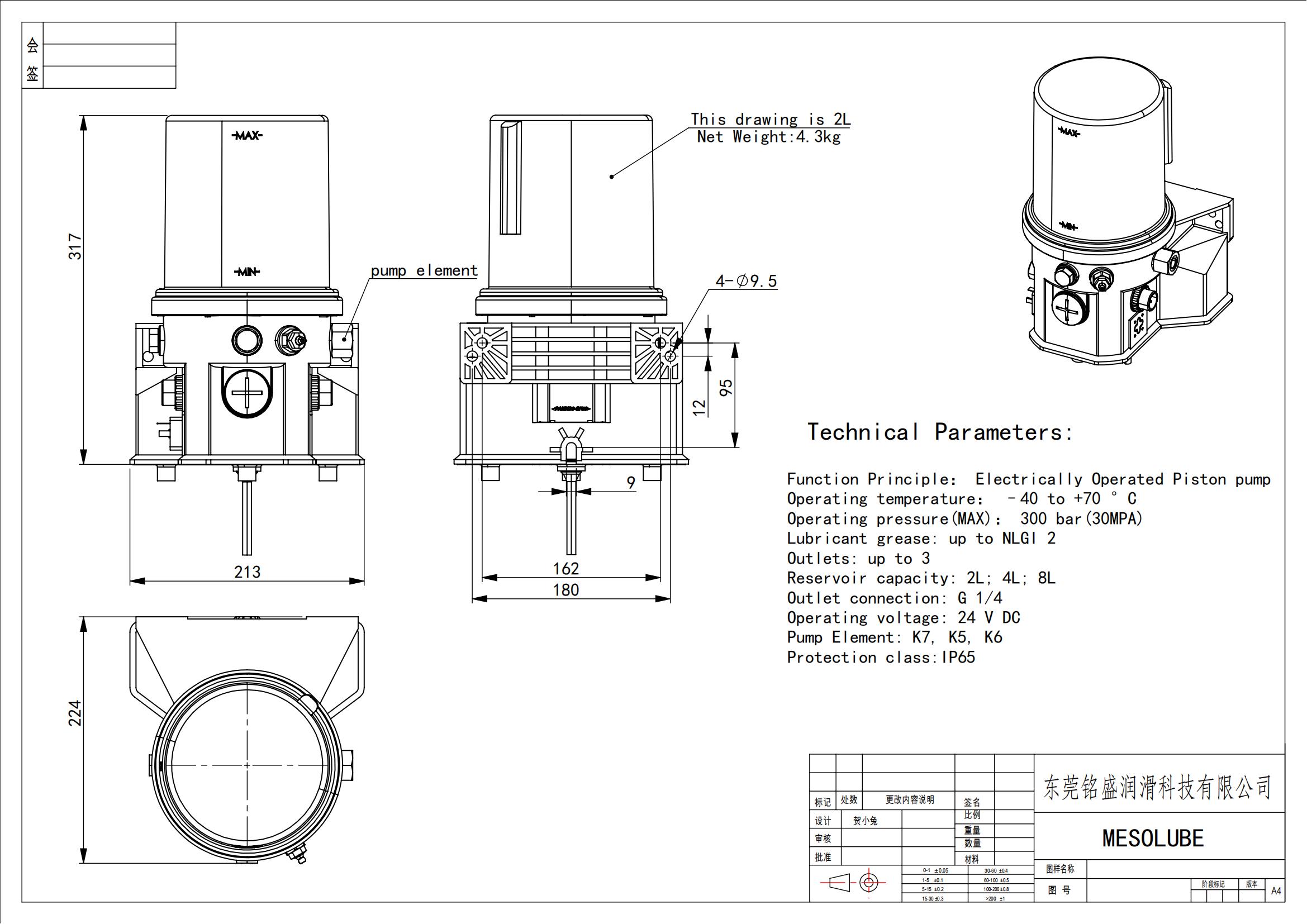

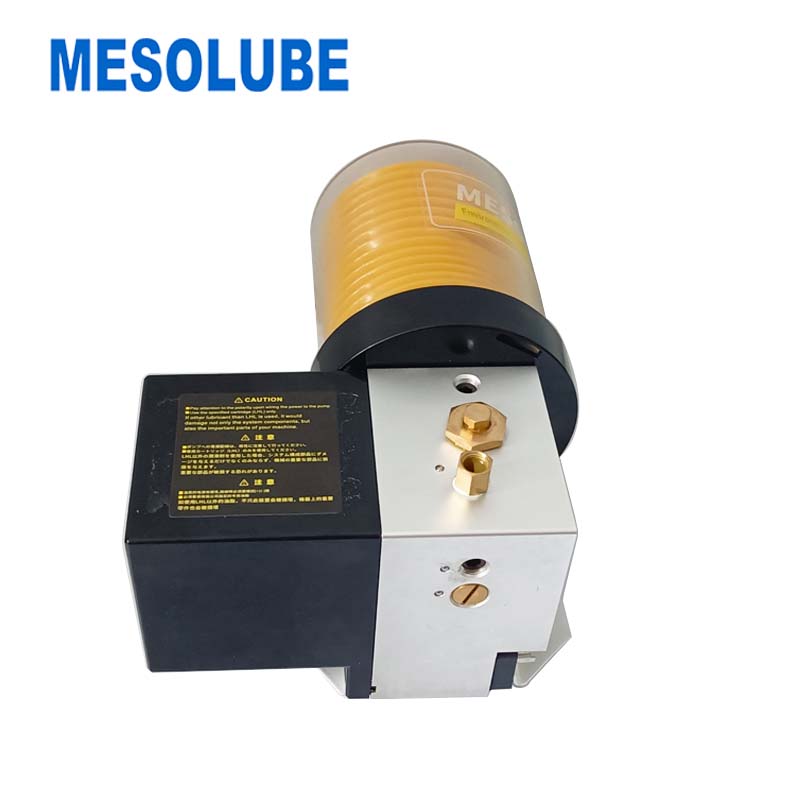

P300-2L Automatic grease Lubrication Pump with controller in a progressive lubrication system

Choosing the Right Electric Grease Pump

When selecting an electric grease pump, consider the following factors:

- Flow Rate: Ensure the pump delivers the required amount of lubricant per cycle.

- Pressure Rating: Check if the pump can handle the pressure needed for your machinery.

- Compatibility: Verify that the pump works well with the type of grease you use.

- Reliability: Opt for reputable brands known for reliable performance.

Description

For progressive lubrication systems

mesolube p300 series is applied automatic lubrication sytem for example in duty industy excavator and machinery machine ,and so on , we couold provide auto progressive lubrication sytsmtem single -line lubricaiton sytem ,This powerful pump can drive up to three pump elements and can be equipped with a low-level control electric grease lubrication pump is used in Excavator equipment ,Lubrication pumps feed lubricant from the lubricant reservoir into the tubing system of the automatic centralized lubrication system. The manometric pressure has to be high enough to compensate for pressure drops in the tubing, components (filters, valves, distributors) and friction points.

Specifications

| Function principle | electrically operated piston pump |

| Operating temperature V DC | –40 to +70 °C |

| Operating temperature V AC | –25 to +70 °C |

| Operating pressure | 350 bar |

| Lubricant | grease: up to NLGI 2 |

| oil with operating viscosity 40–1500 mm2/s | |

| Outlets | up to 3 |

| Metering quantity depending on pump element | 0,7-4,0 cm3/min / outlet |

| Reservoir capacity | 2; 4; 8; 11 and 15 l |

| Outlet connection | G 1/4 |

| Operating voltage | 12/24 V DC |

| 115, 230 V AC / 50 or 60 Hz | |

| Protection class | IP6K9K |

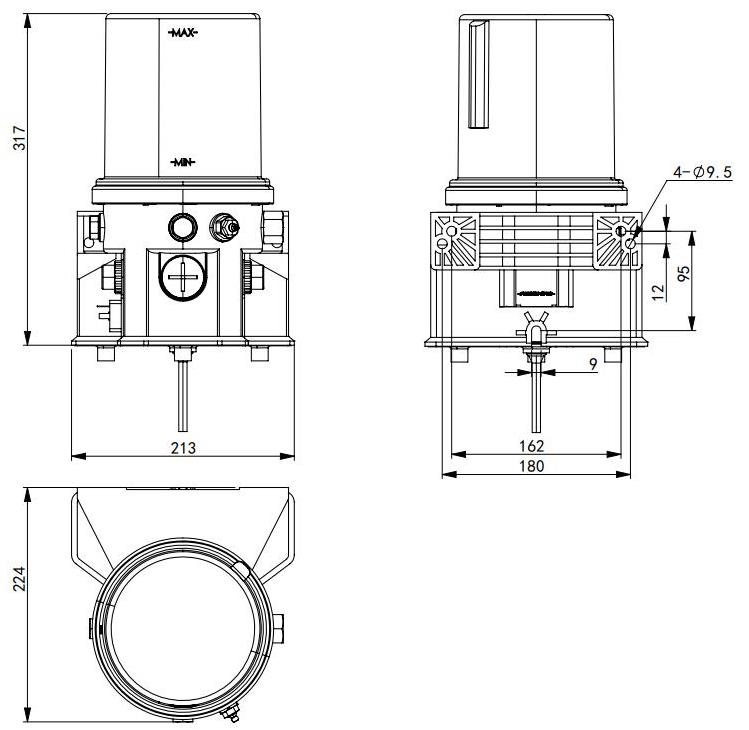

| Dimensions | |

| min. | 211 × 224 × 287 mm |

| max. | 211 × 250 × 774 |

Dimensions

Please contact us for more dimensions!

Applications