D200-416161616 Grease Pressurized distributor

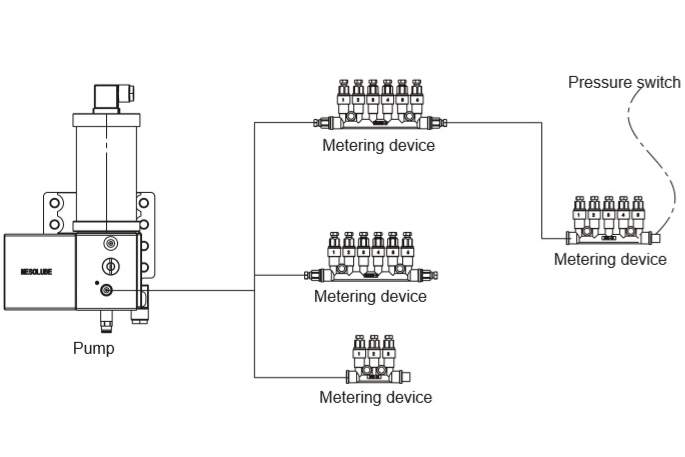

This series of pressurized lubricant metering devices can be combined with various lubricating pumps with pressure relief valves to form a single line lubrication system, system pressure must reach the distributors operating pressure.

Description

1. The grease sent from the pump enters the distributor, so that the umbrella valve in the distributor starts to push upward;

2. After the umbrella valve closes the center hole of the core rod, it forces the piston to overcome the spring force and begin to rise to discharge grease stored in the upper cavity;

3. When the piston moves to the apex of upper cavity, grease discharge is completed at the same time;

4. When the pump stops supplying grease, its pressure-relief valve opens automatically, and the pressure in the main line prompts the pressure-relief valve to return grease. At this time, the system pressure drops and the piston in the distributor begins to recover under the action of the spring. When the umbrella valve returns to close the inlet of distributor, the piston presses the grease stored in the lower cavity to the upper cavity through the small hole of the core rod, and the grease storage work is completed.

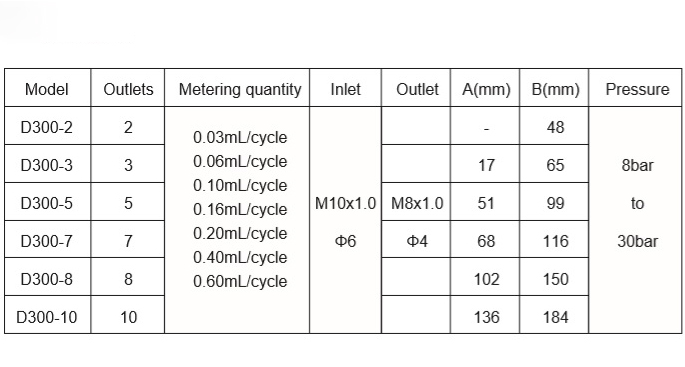

Ordercode

Specifications

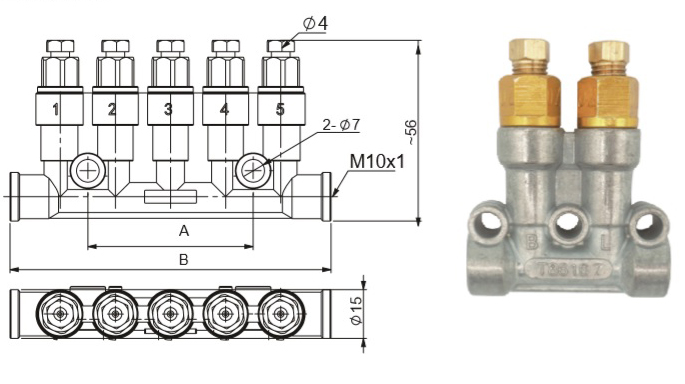

Dimensions

Applications