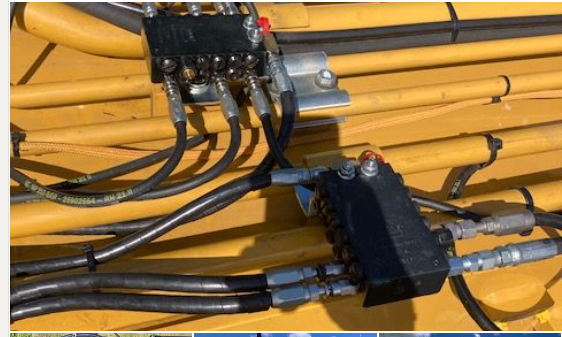

D100-SSV6 Progressive Distributor for Construction machinery

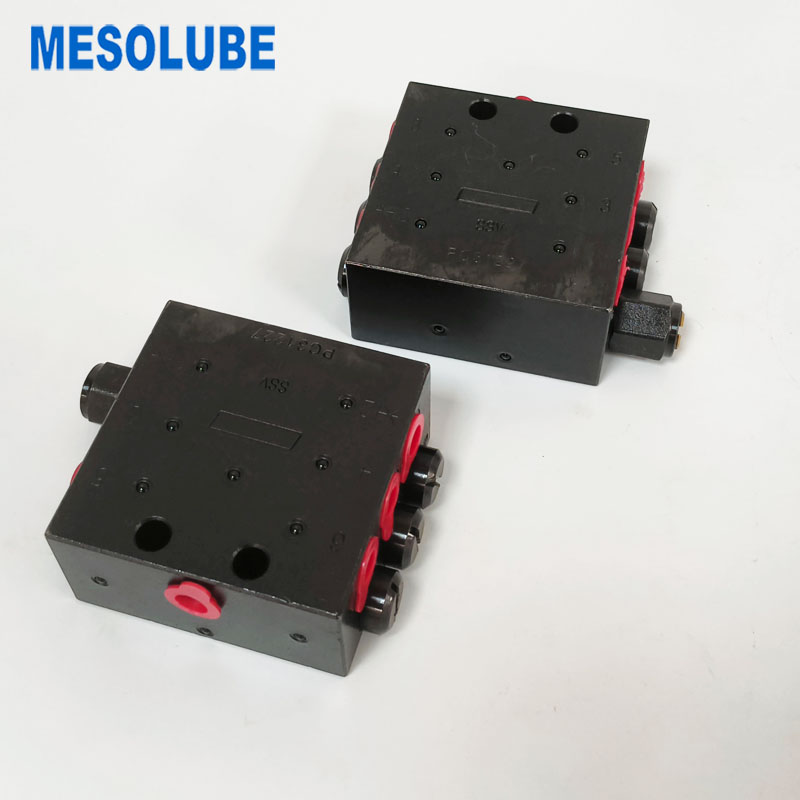

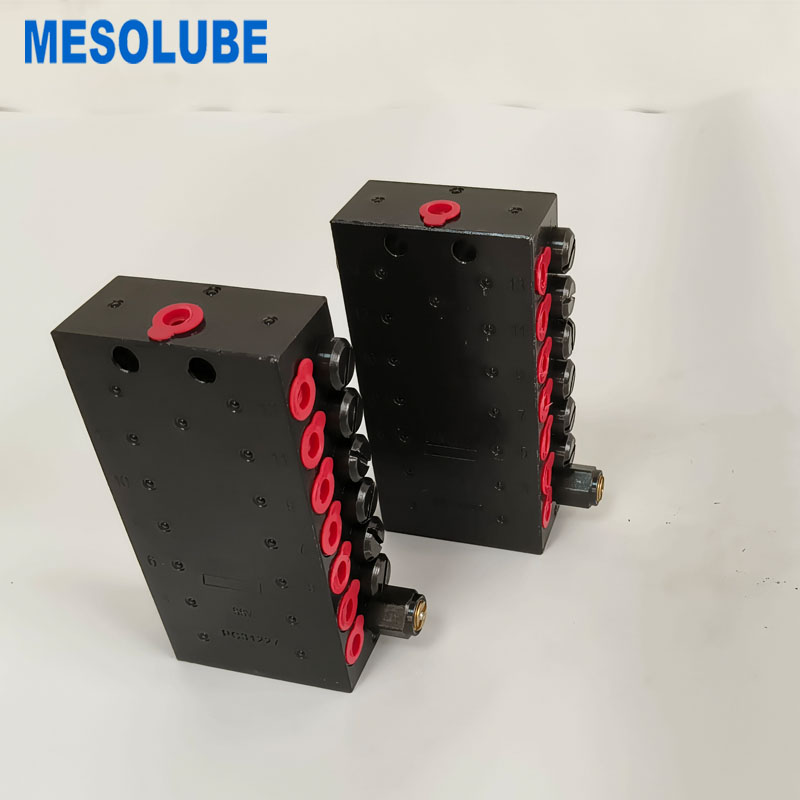

The metering quantity of each outlet is 0.2mL per cycle. When one or more outlets are closed, the discharge changes in multiples. A metering device with 6-12 outlets can be selected, up to 22 outlets. Lubricant used: Mineral grease below NLGI2.

Description

D100 series metering device is suitable for all progressive centralized lubrication system.

Characteristics

D100 series metering device is plunger type.

It automatically distributes the lubricant from the pump to the connected lubrication points.

The metering quantity of each outlet is 0.2mL per cycle.

When one or more outlets are closed, the metered quantity of each outlet changes in multiples.

A metering device with 6-12 outlets can be selected, up to 22 outlets.

Lubricant used: Mineral grease above −40mm²/s(cS), or grease below NLGI2.

Mounting

Install the metering device at the appropriate place according to the lubrication diagram.

It is recommended that when mounting the metering device, do not allow the outlet to be too close to the installation bottom plate, otherwise it will not be easy to troubleshoot when the system is blocked.

When mounting a metering valve with pointer, it must be ensured that its pointer is easy to observe visually.

When using quick connectors, please pay attention to the following issues:

The inlet of metering device, only quick connector with reinforced buckles and sealing rings can be used.

For high-pressure hoses (Φ8.6×2.3mm), quick connector with reinforced buckles and sealing rings should be used; for plastic hoses (Φ6×1.5mm), quick couplings with oil threaded buckles should be used .

Note: For construction machinery and agricultural machinery, high-pressure hoses should be used for the lubrication line. In this case, both the second-level metering device and the pipe joints at the lubrication point can adopt quick joints with reinforced sealing rings.

Only use the lubrication pipeline designated by our company and meet the specified system pressure requirements.

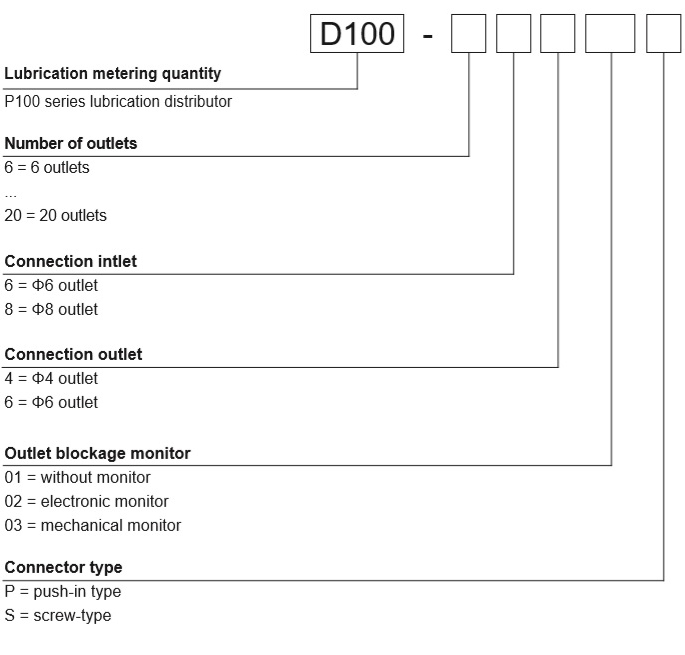

Ordercode

Specifications

| Metering quantity Connection outlet Inlet thread Max operating pressure Min operating pressure Lubricant Monitor Material Max pressure difference at outlet Operating temperature |

0.2mL/cycle Φ4 Φ6 G1/8 35MPa 2MPa NLGI 000~2 Indicator pin aluminum 10MPa -25°C to 70°C |

| Quick & Screw Connector High pressure zone max pressure Main distributor inlet & outlet Low pressure area max pressure Second-stage distributor outlet Lubrication point connector |

Quick & Screw Connector 35MPa Φ8 Φ6 25MPa Φ6 Φ4 |

| Main-line Min rupture pressure Min bending radius Min temperature Branch-line 20°C burst pressure Min bending radius Mini temperature |

Main-line 60Mpa 35mm -40℃ Branch-line 50mm ~21MPa -40℃ |

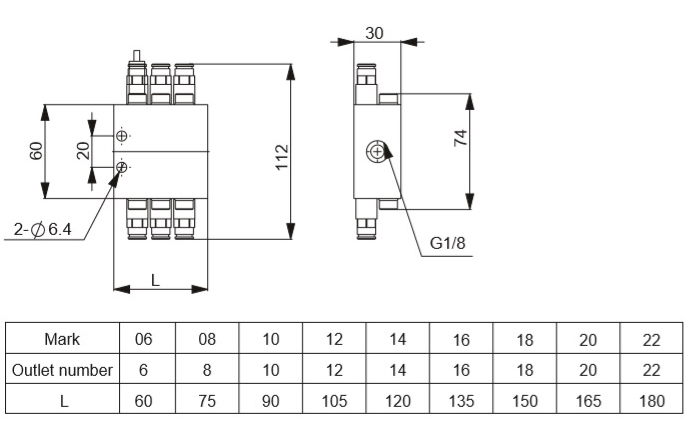

Dimensions

Applications