Introduction to Mesolube Progressive System

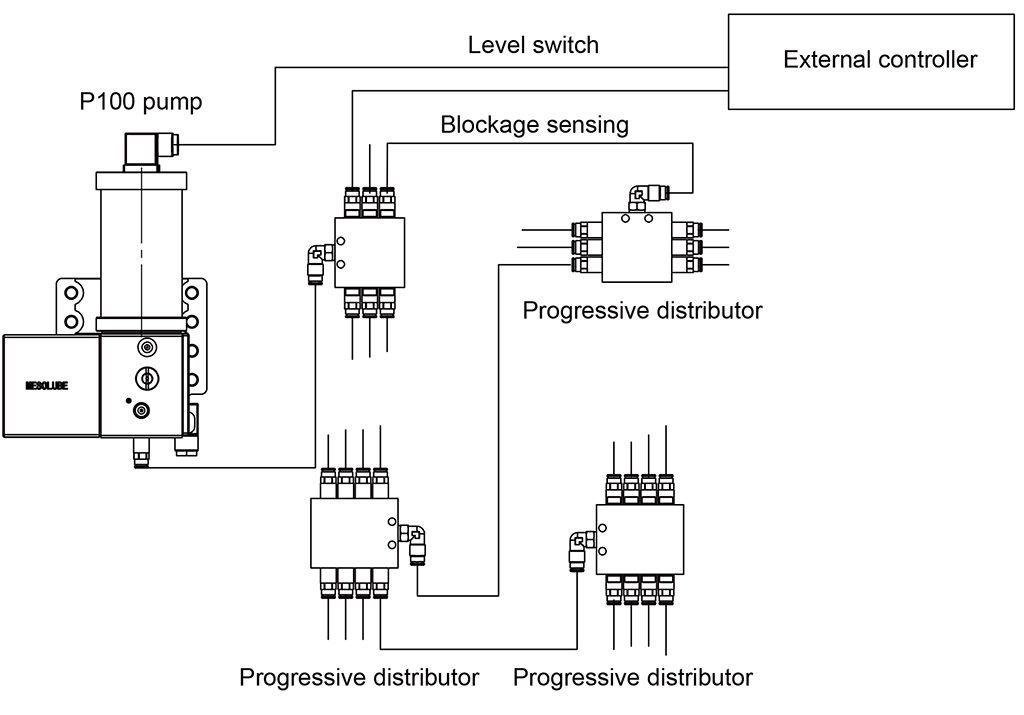

The progressive lubrication system consists of at least one pump and one main metering device. According to work needs, a secondary metering device can be connected to the outlet of the main metering device to increase the number of lubrication outlets. The primary and secondary metering devices are connected to the lubrication point of the equipment through a branch line. It is not recommended to connect the tertiary metering device without special circumstances.

The main feature of the progressive lubrication system is shown in the progressive lubrication metering device. Due to the particularity of the working principle of the progressive metering device, once a certain outlet of the metering device is blocked by the outside, the entire metering device will stop working, and the stop of the entire metering device will cause the stop of the entire progressive system. Using this feature, a travel switch can be installed on a certain metering device to control and monitor the operation of the entire system and perform fault diagnosis.

Features of Mesolube progressive system

(1) The distance between lubrication points is relatively close, which is suitable for small and medium-sized systems;

(2) The fault can be quickly judged and the grease can be discharged from the safety valve in time; it is helpful to protect the equipment.

(3) Extend the system through pump elements

(4) Multiple lubrication parts (several to hundreds of uniform lubrication) can be applied.

(5) It can lubricate 800 points at the same time, and the line is more than 100 meters long.

Application of Mesolube Progressive System

Construction machinery: pump trucks, rotary drilling machines, pavers, cranes, etc.

Wind power: wind turbine pitch, main shaft, yaw and other parts.

Water conservancy industry: portal cranes, bridge cranes, ship lifts, etc.

Commercial vehicles: buses, trucks, pump trucks, fire trucks, excavators, tractors

Industrial machinery: ironmaking/steelmaking equipment, rolling mills, casting machines, injection molding machines, presses, cutting machines, papermaking machinery, waterwheels/sluices, working machines

Handling and unloading machinery: suspension cranes, container cranes, ship unloaders, boom cranes, storage yard loading conveyors.

Civil engineering equipment: crushers, drilling machines, rock drills, ready-mixed concrete, asphalt concrete mixers.

Others: food and beverage machines, packaging printers, wood equipment, cement equipment kilns, incinerators, blowers, hair dryers, reducers, accelerators.