.

Understanding the Functions of Lubricants

- Reducing Friction and Wear: Lubricants create a protective layer between moving parts, minimizing wear and tear. This enhances efficiency and reduces maintenance requirements.

- Protection Against Corrosion: Harsh environmental conditions can lead to metal corrosion. Lubricants act as a barrier, preventing direct contact with moisture and chemicals.

- Controlling Contamination: Formulated to resist dust and dirt ingress, lubricants keep internal components clean, maintaining machinery efficiency.

- Temperature Management: Lubricants dissipate heat from moving parts, preventing overheating and associated damage.

Types of Lubrication Systems

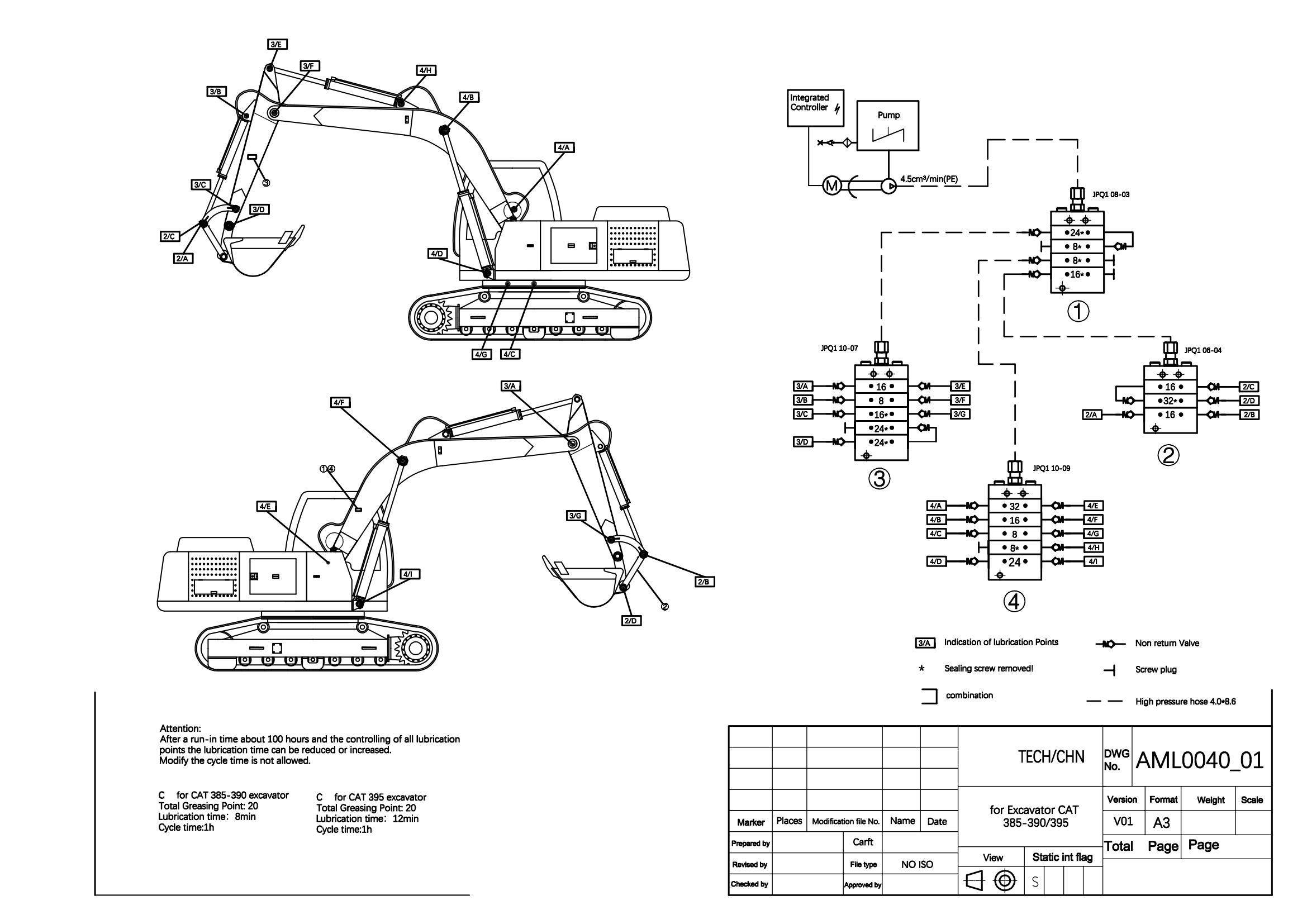

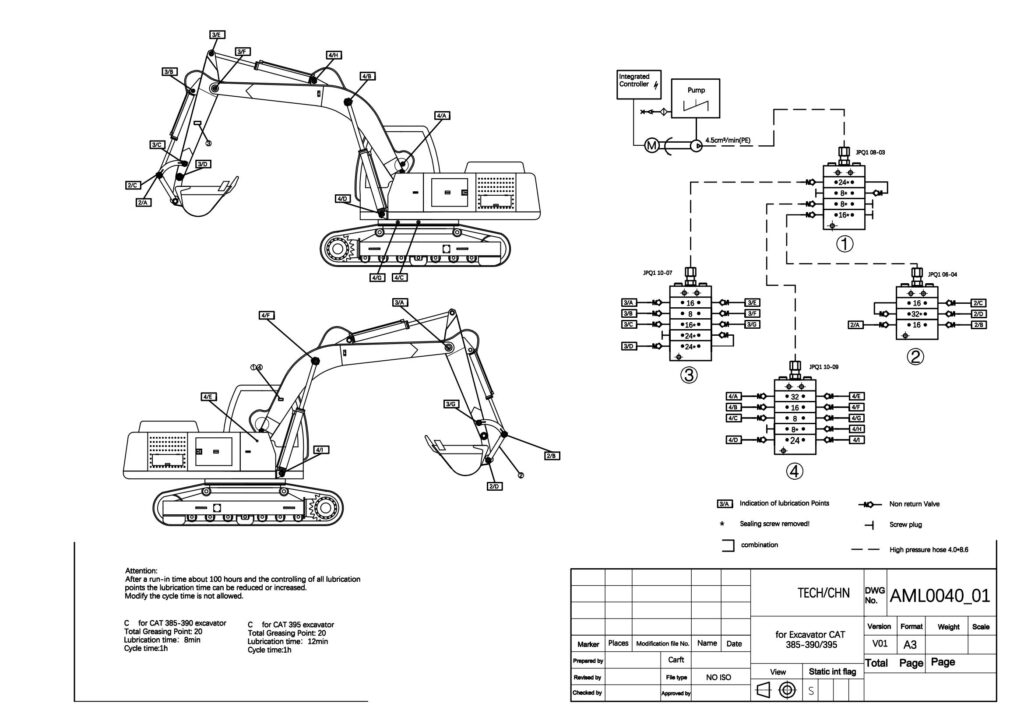

- Automatic Progressive Lubrication System:

- This system gradually delivers lubricant to various points in the excavator.

- It uses progressive divider blocks to distribute grease or oil.

- These systems are reliable and suitable for heavy machinery like excavators.

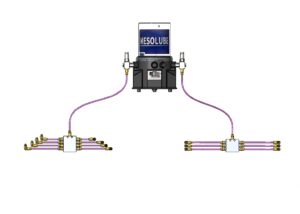

- Centralized Automatic Lubrication System:

- A centralized system delivers lubricant to multiple points simultaneously.

- It ensures consistent lubrication and reduces manual effort.

Factors to Consider

- Application:

- Consider the excavator’s specific requirements, such as load, operating conditions, and environmental factors.

- Cost:

- Evaluate the initial investment, maintenance costs, and long-term savings.

- Real-World Applications:

- Learn from case studies and industry experts to understand practical benefits.

- Consult Experts:

- Reach out to lubrication system providers or consult with maintenance professionals to tailor the system to your excavator’s needs.

Remember that a well-designed lubrication system not only enhances performance but also contributes to the overall durability of your excavators12. ?️?