Mesolube Technology

Mesolube has a professional technical team that can design and produce lubrication pumps, lubrication metering devices, lubrication accessories and other products, and can provide targeted centralized lubrication system solutions to solve the lubrication needs of various equipment. Our products are mainly used in various key parts of non-standard automation equipment, such as chains, electric motors, gear racks, open gears, roller and sliding bearings, shaft seals, sliding guides, spindle, etc.

Technicians

We have a professional lubrication system research and development team, and the average work experience of team members has reached more than 8 years. Before the establishment of the company, our technical team members focused on different fields related to centralized lubrication systems, such as hydraulic technology, machine tool accessory research and development, and lubricant production. Today, we have gathered various directors to form this professional lubrication system R&D team. Since our team is composed of professionals in different fields, the lubrication pumps we develop now pay more attention to stability and durability. Moreover, because of our comprehensive control of the lubrication system, our products will be more in line with market needs, in line with advanced design concepts, and can keep pace with the times.

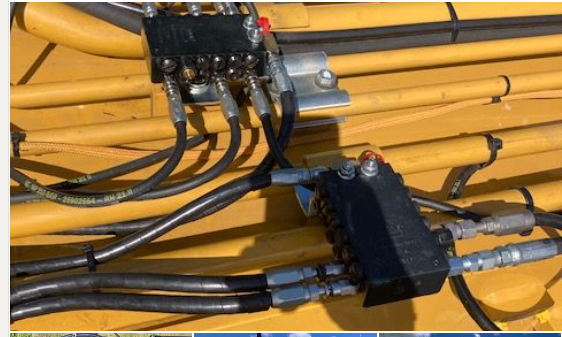

Manufacturing

Our products are advancing with the times in design concepts and technology, and have good stability and durability. In order to ensure that our products are stable, durable, efficient, and cost-effective, when selecting production materials, we repeatedly screen and test among many materials, choose the best material, and then choose the manufacturer that we cooperate with. On the other hand, the design of our products is very flexible. For example, on a pump component, it can be assembled into a reservoir model or a cartridge model to suit different needs. Due to this flexible design, the production cycle of the product is very short, and at the same time, it enables us to update the product in time according to the market demand, and it is also suitable for customizing products for customers.

Testing

The production process of our products is implemented in accordance with the ISO international quality system standard process, and each production step and the production quality of each product are monitored throughout the process. Before our lubrication pumps are put on the market, all of them must pass strict tests. Including high and low temperature testing, air tightness testing, air pressure testing, current and voltage testing, durability testing, etc. We ensure that each product meets the requirements before completing the production process.

Shipping

Logistics and transportation are an important link. We are always trying to save time and cost. We have explored a good shipping method, established a warehouse, and are constantly improving, which involves inventory, distribution, classification, packaging, etc. In terms of transportation, we coordinate with various companies in order to obtain dedicated logistics channels. MESOLUBE products have been sold to more than 80 countries around the world, including the United States, Spain, France, Russia, Germany, Italy, Australia and South America.

Service

We have a one-year warranty for the main components of the lubrication pump, provide 24-hour consulting services, and provide installation, commissioning, and maintenance instructions according to customer needs. In order to better serve our customers and facilitate the daily use of lubrication pumps, we have developed a set of after-sales service system. If the product fails, you can submit it on the system, and we can respond quickly and provide you with services as quickly as possible. You can also post comments, ask questions or service suggestions, and track the progress of the service at any time.