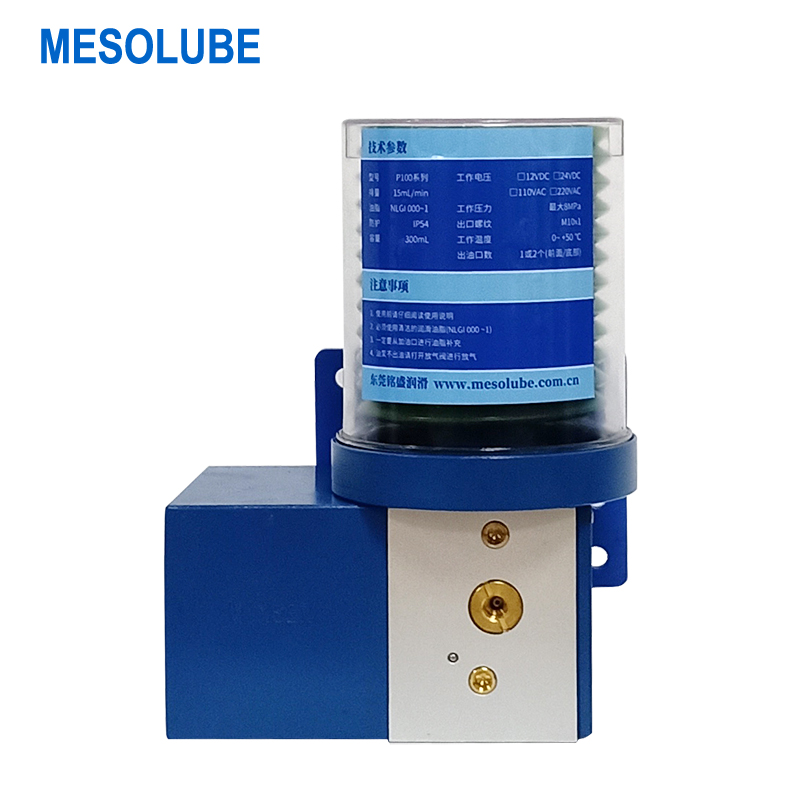

P100-0.2reservoir automatic Lubrication Pump for bearing of motor

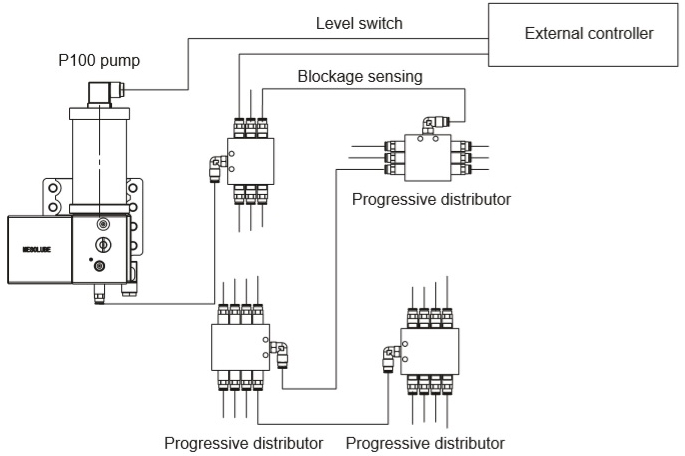

The pump can be connected to a pressurized distributor to form a single-line system, and to a progressive distributor to form a progressive system. The main line of the system can be up to 15 meters long and can lubricate up to 100 points.

Description

Series Features

1. Two versions with reservoir or cartridge

2. Up to 2 lubricant outlets

3. With liquid level monitoring function

4. Woltage 12/24VDC,

5. Max operating pressure 8MPa

6. Controlled by external PLC or with controller

7. Six optional mounting bores offer variety of installation possibilities

8. Manual lubrication button to facilitate system startup or exhaust

9. Venting screw for simple venting during system start-up or after cartridge exchange

10. Indoor use

Progressive System Features

The max length of the lubrication pipeline of the progressive system can reach 14 meters

When the system fails and the distributor is blocked, the system will alarm.

The lubricant can be distributed to each lubrication point in a predetermined proportion

With visual monitoring or electrical monitoring function

If the system is blocked, it can be seen from the safety valve that there is grease overflow.

Specifications

| Model | P100 series |

| Operating pressure | Max 8MPa |

| Operating temperature | 0~+50 °C |

| Metering quantity | 15mL/min |

| Operating voltage | 12VDC, 24VDC, 110VAC, 220VAC |

| Protection class | IP54 |

| Number of outlet | 1or2 (front and/or bottom) |

| Lubricants | NLGI 000~2 (Working stable lithium soap grease) |

| Cartridges | 0.2L 0.3L, 0.4L, 0.7L |

| Reservoirs | 0.5L, 0.7L, 1.0L, 1.2L, 1.5L |

| Mounting position | Upright |

Applications

Automation, Machine tools, Material handling, Plastic-injection-molding machinery and processes